Fabricación de chapa personalizada

Custom Sheet Metal Fabrication

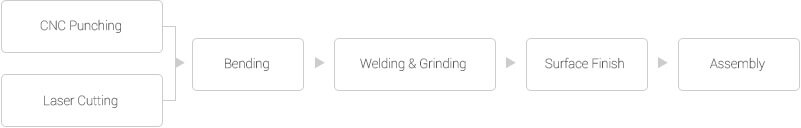

Sheet Metal Production Process

For any sheet metal part, it has a certain manufacturing process, so-called process flow. With the difference in the structure of sheet metal parts, the process flow may be different. The process described below is mainly what our factory can do. Our metal fabrication facilities allow us to work on a vast range of work pieces. We are capable of fabricating small to large assembly work including high integrity machined components.

-

Metal CuttingWe have Amada CNC punching machine, laser cutting machine, and flame cutting machine for sheet metal cutting.

Metal CuttingWe have Amada CNC punching machine, laser cutting machine, and flame cutting machine for sheet metal cutting. -

StampingWe have our own tooling design & manufacturing workshop, and 10 sets punch press machine for precision stamping parts.

StampingWe have our own tooling design & manufacturing workshop, and 10 sets punch press machine for precision stamping parts. -

BendingWe have 4 sets bending machine, 3 sets for sheet metal, 1 set for heavy steel.

BendingWe have 4 sets bending machine, 3 sets for sheet metal, 1 set for heavy steel. -

Press RivetingWe have 2 sets pressure riveting machine to realize the reliable connection of two parts.

Press RivetingWe have 2 sets pressure riveting machine to realize the reliable connection of two parts. -

Powder coatingWe have our own painting line that meets the environmental requirements of the government, to provide one-stop metal fabrication for customer’s different requirements.

Powder coatingWe have our own painting line that meets the environmental requirements of the government, to provide one-stop metal fabrication for customer’s different requirements. -

Inspection EquipmentWe have quality inspection process in accordance with ISO9001:2008.

Inspection EquipmentWe have quality inspection process in accordance with ISO9001:2008.

Cutting

Bending

Welding

Powder Coating

Sheet Metal Material

- Aluminium

- Carbon Steel

- Stainless steel

- Brass

- Copper

Sheet Metal Finish

Self--owned

- Powder Coating

- Painting

- Sandblasting

Outsourced

- Anodize

- Zinc Coat

- Chromeplate

- Silk-screen

- Brush

- Mirror Polish

Sheet Metal Application

- CABINETS Sheet metal offers a cost-effective way to fabricate product device panels, boxes and cases for a variety of applications. We build enclosures and cabinets of all styles.

- BRACKETS Builds custom brackets and miscellaneous sheet metal components, well-suited for either lightweight applications or when a high degree of corrosion-resistance is needed. All hardware and fasteners that are needed can be fully built in.

Custom Tooling Manufacturing

Tooling R&D

Tooling is the process of designing and engineering the tools that are necessary to manufacture parts or components, building sheet metal stamping dies and tooling has been the heart of CSCM. For cold forming, sheet metal, precise manufacturing, continuous evaluation of our process, we have our own tooling engineer team to design and manufacturing stamping die to cost down tooling cost for both clients and us.

Why Is Tooling Important?

The quality of a finished part, its properties, the speed and accuracy with which it can be produced and the repeatability of manufacture in high volume production runs, all depend on the precision and characteristics of the tooling. So for the best parts, tooling needs to be designed and engineered to the highest quality.

Tooling Material:

- 45#

- CR12

- CR12MOV

- SKD11

Tooling life:

- Cold plate, 10,000 shots--20,000 shots

- Normal, 200,000 shots--300,000 shots

Total 1 Página 2 archivos